Top Health gelatin capsules

Empty

hard gelatin capsules

Reliable and consistent two-piece capsules

Empty hard gelatin capsules have been top health’s key products from company’s foundation. For over 30 years, Top health has been providing quality capsules to the customers all over the world. Providing the all documents which required by clearing the customs in various countries. 30 billion capsules sold in over 20 countries globally, serving over 40% of Asia’s pharmaceutical prescription market, but also have been exported to most countries in Europe, USA, South East Asia, South America etc., which have accounted for 20% of the global market.

RAW MATERIAL

In order to ensure of quality goods to the customer, the right kind of materials are procured from the right source, the principal raw materials involved include EDQM certified TSE/BSE free Gelatin and color pigments.

1.Color pigment:

Colorants are used as per specific requirements of customers. Top Health providing Customers exact color shades as per their customized requirements. The color shade is consistent in all the batches of production. The color pigments used are strictly as per CP, USP/EP. The color shade ones developed for customer is allotted a code and is always reproduced on repeat of order.

2.Gelatin:

We are using bone gelatin of pharmaceutical grade ( as per CP or USP ), which is always free from BSE and TSE. Strictly HALAL & EDQM certified.

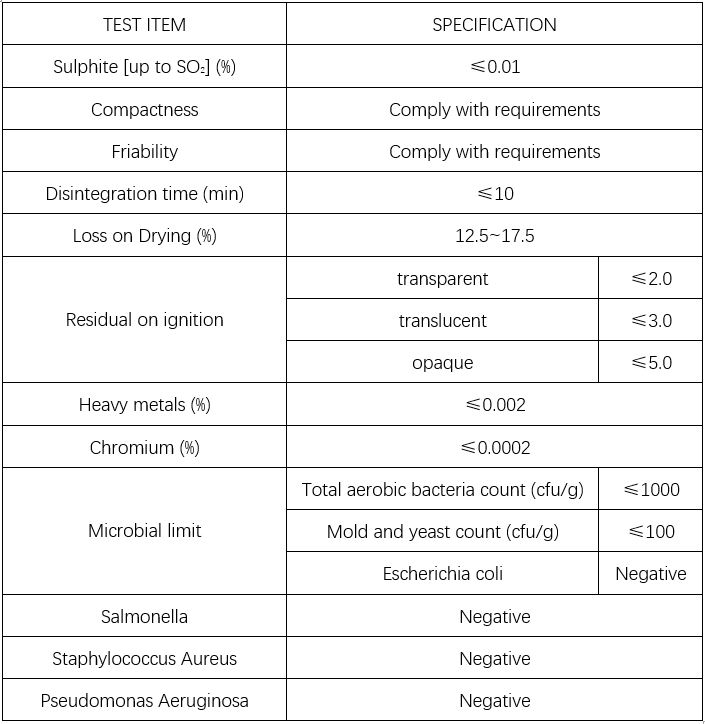

3.Standards:

Our product is complying with specifications as per CP & also compils to USP & EP in terms of Dimensions, Brittleness, Uniformity of weight, Disintegration Time, Microbiological Limits, Loss on Drying, Storage and Labeling. We maintain quality better than Specified in C.P. as per the Specification Sheet of Top Health Capsule Limited.

STORAGE

Capsules should be stored in dry and cool place and boxes should be well closed. The relative humidity is kept between 35% and 65%. The temperature should be between 15℃ to 25℃.

ADVANTAGES OF TOP HEALTH GELATIN CAPSULES

1.Block the bitter taste and unpleasant smell of the drug itself, so that patients can easily take it.

2.Extra packing enhancing bioavailability.

3.Slow-release action, preventing rapid digestion and absorption of the drug until it enters a specific area before it acts normally.

4.Complete range of articles

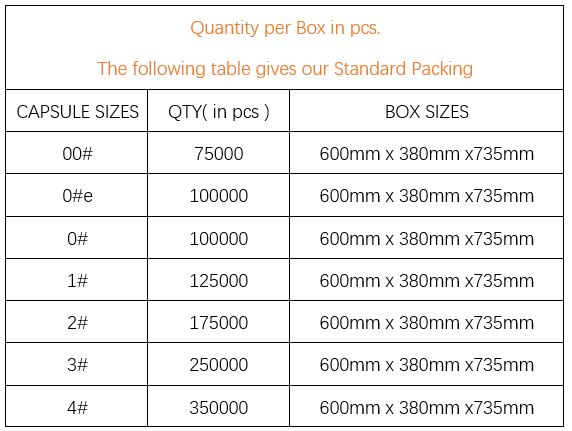

We are capable to produce several versions of vacant capsule, such as 00#、0#E、0#、1#、2#、3#、4# and so on in our company.

5.Advanced equipment

We own advanced production process, equipment and high-quality raw materials to provide high-quality vacant capsule with wholehearted service.

PACKAGING AND LABELING

1.Export Packing

In order to protect capsules from severe and fluctuating conditions of temperature and humidity, we pack the capsules first in Poly Bags, then these bag are put in “Aluminum Foil LLDP co-extruded bags”. These bags are then put in corrugated box, which is lined with Thermocol ( Styrofoam ) on all the six inner sides of the box. Further these packed boxes are then laminated with poly film. Thus, we not only take care of the temperature and humidity but also take into consideration the mis-handling that might take place during transportation.

STANDARD PACKING

2.Labeling

Labeling being subset of packaging, the cartons are properly labeled indicating basic information viz., Size, Colour, Quantity, Storage Conditions, Destination etc. Visual test are conducted to ensure that the script is legible and colours are harmonious.

Proper markings, box numbers and sample capsules/capsules color image is paste on each box which helps in easy visual identification of Provide.